|

设计简介 |

设计描述:

文档包括:

word版说明书一份,34页,12000字左右.

外文翻译一份

CAD版本图纸,共7张:

摘要:塑料工业是一门新兴产业,自塑料问世后几十年,塑料来源丰富,制作方便及成本低廉、金属零件塑料化的发展很快,在机械电子、国防、交通、通讯、建筑、农业、轻工业和日常生活用品等行业中都得到了广泛的应用,对塑料模具要求量增加。因此,研究注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。

本设计介绍了注射成型的基本原理,特别是单分型面注射模具的结构与工作原理,

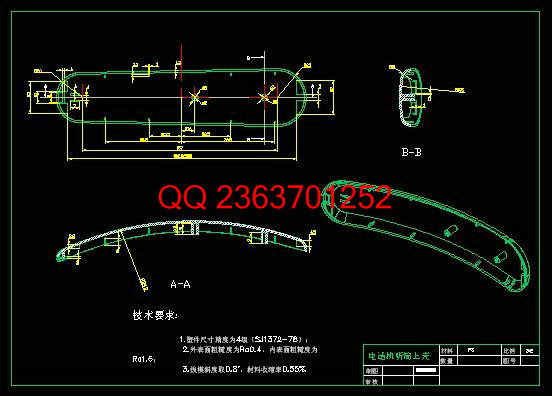

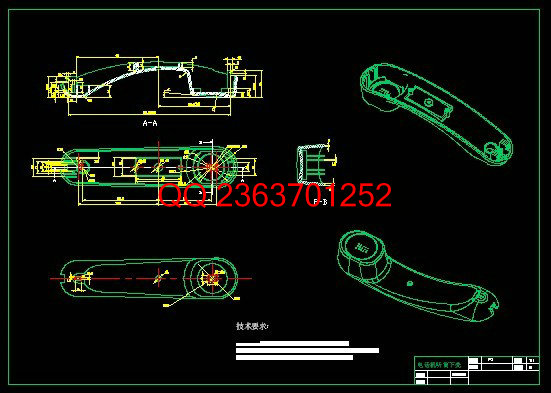

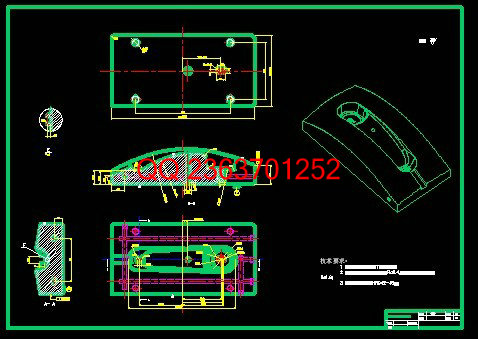

对注塑产品提出了基本的设计原则;通过对绕流板支架工艺的正确分析,设计了一副一模两腔的塑料模具。详细地叙述了模具成型零件包括前模板、前模仁、后模板、后模仁、后模镶件、斜导柱、滑块等的设计与加工工艺过程,重要零件的工艺参数的选择与计算,推出机构与浇注系统以及其它结构的设计过程,综合地处理好产品外观要求与浇口位置及脱模方式之间的问题,并对试模与产品缺陷作了介绍。

关键词:模具设计、常用塑料

Abstract:Plastics industry is an emerging industry, since several decades after the advent of plastic, plastic source of rich, convenient and low-cost production, plastic and metal parts of the developed rapidly, in machinery and electronics, defense, transportation, communication, construction, agriculture, light industry and daily necessities, such as industry, have been widely used on the plastic mold requested increase. Therefore, the research casts the mold to understand the plastic product the production process and improves the product quality to have the very big significance.

This design introduced the injection takes shape the basic principle, specially single is divided the profile to inject the mold the structure and the principle of work, to cast the product to propose the basic principle of design; A set of mould with one module and two cavities has been designed through he flow around the right boards sent technology analysis. The design and machining technology process of its molding part including the front molding plate、front mould kernel、back mould plate、back mould kernel、back mould set piece、incline guide pin、slide steatite etc, and the choice and calculation of technology parameters of the impotent part, the design process of extrusion outfit, inject system and other makeup are specified in detail; integrated approach to the appearance of a good product demand and gate location and the way the problems between Remolding, Test and product have been introduced.

Key Words: Mold Design and Manufacturing、Conventional Plastic Materials

目 录

第1章 绪论 1

1.1 注射成型模具的地位及发展趋势 1

1.2 毕业设计选题的背景、设计方法、目的和意义 2

第2章 塑件工艺性及成型工艺条件 3

2.1 电话机听筒外壳制品图 3

2.2 塑件结构工艺性分析 4

2.3 塑件成型工艺条件分析 4

第3章 成型设备 6

3.1 成型设备的选择 6

3.2 注射机基本参数的校核 6

第4章 模具的结构设计 9

4.1 型腔数目的确定和排列方式 9

4.2 分型面的选择 9

4.3 浇注系统的设计 10

4.4 成型零部件的设计 11

4.5 脱模机构 15

4.6 抽芯机构 16

4.7 调温系统 18

4.8 导向机构 26

4.9 排气系统 26

第5章 模具的安装及调试 28

5.1 模具的安装 28

5.2 模具的开合动作分析 30

5.3 试模 30

结论 33

致谢 34

参考文献 35

|