|

|

|

|

设计名称 |

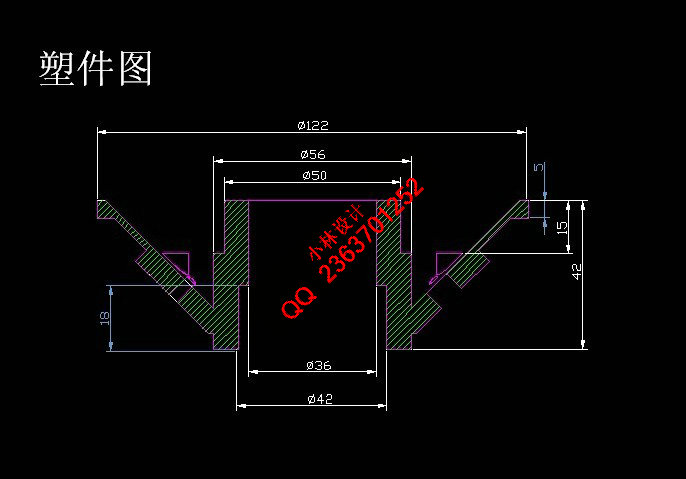

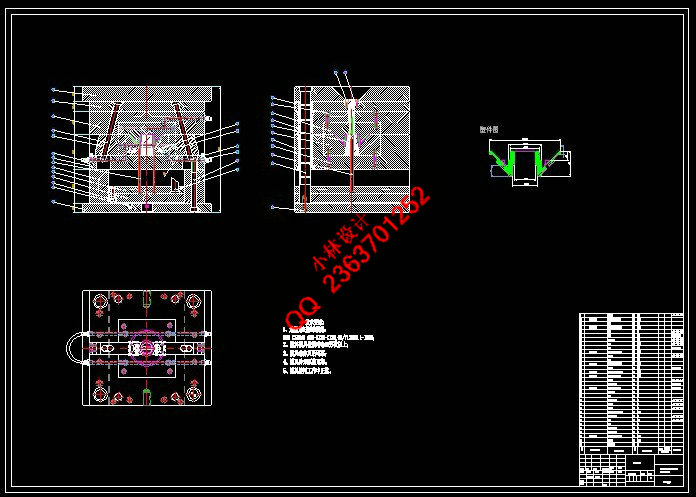

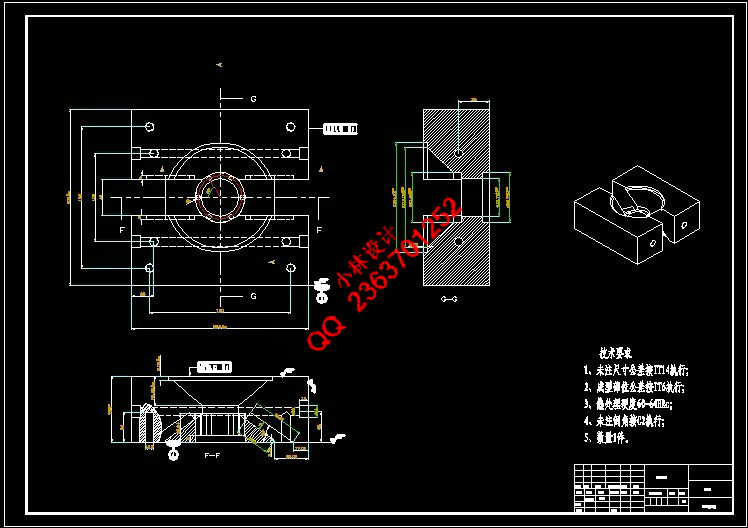

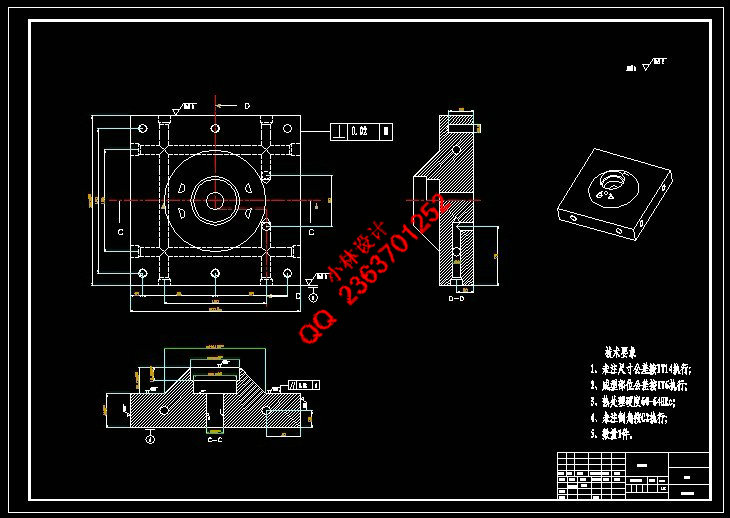

喷雾器喷头斜抽芯注射模设计 |

|

|

设计编号 |

W308 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

13000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

该塑件采用PVC为材料,然后在分析计算的基础上确定成型工艺方案,为一模4腔,推杆推出,点浇口,单 分型面,浇口套内的主流道采用圆锥形,选用的模架为标准模架的A1型,导柱导套的安装用Z1的安装方式 ,再在此基础上进入模具总装配图的结构设计以及尺寸的确定。在此基础上对注塑模具的主要零部件尤其 是成型零部件的尺寸进行设计与计算,期间要参考塑料成型相关的资料和翻阅各种塑料模具设计手册,并 通过计算以确定模具的具体结构及尺寸以及成型零件的相关尺寸,通过不断的计算与修改,并在指导老师 的悉心关怀和耐心指导下进行不间断的反复修改,最终独立完成这次毕业设计。在设计的过程中,主要成

型零件采用镶拼结构,利于加工。

Design Of Spray Nozzle Inclined Core-Pulling Injection Mould Abstract: The graduation project is the subject of spray nozzle injection mold design.First, the products are analysed and calculated as to the process of the design, with the products use PVC plastic parts as its material, and then the production process of a 4 cavity mold, putting launch point gate, single typeface, comprising the main gate with conical channel, selected as the standard mold of the A1-type mold, guide pins and bushings and installation methods with the Z1 installation is established, on the basis of the scientific calculation and analysis. On this basis, the structural design of the total assembly drawingand size is determined. Then, the main components of the injection mold molded parts, especially the size of the design should be calculated, during which processes, the relevant information and reading of all kinds of plastic mold design manual should be obtained, and the specific structure of the mold and size should be calculated and revised continually before determined. With the careful and patient guidance of instructor, as well as constant revise, ultimately an complete graduation project should be done independently. In the

design process, the main use of mosaic structure of the molded part benefits processing. 目 录

摘 要 1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!