|

|

|

|

设计名称 |

Y向箱体机械加工规程及编程 |

|

|

设计编号 |

A375 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

8000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

||

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

说明书1份,共36页,约8000字左右

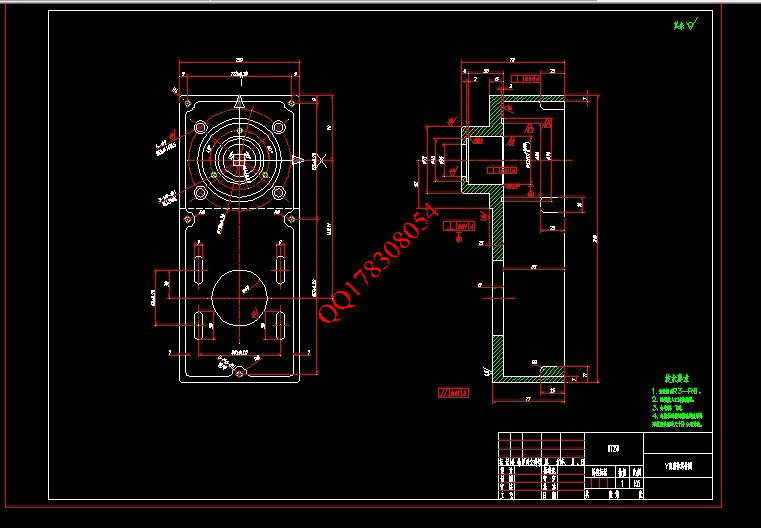

CAD版本本图纸,共2张

摘要

本篇设计是Y向箱体加工工艺及编程,Y向箱体零件的主要加工表面是各表面的铣削加工,内表面的铣削加工和及内孔 , , 的镗削加工以及 直孔的钻削加工和8-M6-6H螺纹孔的钻、攻加工等。一般来说,保证平面的加工精度与保证孔系的加工精度相比,保证平面的加工精度比较容易。孔径加工都是选用专用钻夹具,夹紧方式一般选用手动夹紧,夹紧可靠。因此生产效率较高。能够满足设计要求。

文章的重点在于对Y向箱体的工艺性和力学性能分析,对加工工艺规程进行合理分析,对Y向箱体进行加工工艺的规程设计,包括了Y向箱体的数控铣削加工,并且介绍了数控铣的加工工艺及编程,以此Y向箱体进行数控铣的加工工艺编制和数控编程的设计,经过实践证明,通过合理地安排该Y向箱体的机械加工工艺路线,能够加工出合格的Y向箱体零件,以便于其他零部件的装配。

关键词:加工工艺;Y向箱体;编程;数控

目 录 摘 要 第一章 前言 ··········································································01 第二章 Y向箱体的结构分析 ······················································01 2.1 零件的作用 ····················································································03 2.2 零件的分析 ····················································································03 第三章 Y向箱体加工工艺设计 ···················································05 3.1 确定毛坯的制造形式 ········································································07 3.2 基面的选择 ····················································································09 3.3 确定主要加工表面加工方法 ·······························································10 3.4 加工阶段的划分 ··············································································13 3.4.1划分准则 ·················································································15 3.4.2时效处理的安排 ········································································17 3.5 制定工艺路线 ·················································································20 3.6 加工机床及刀具的选择 ·····································································22 3.7 机械加工余量、工序尺寸及毛坯尺寸的确定 ··········································23 3.8 确定切削用量和工时计算 ··································································25 第四章 Y向箱体的编程 ·····························································27 4.1 数控加工对刀 ·················································································28 4.2 加工程序编制 ·················································································29 4.2.1 铣铸件左右表面及 4.2.2 镗 第五章 结论 ···········································································32 第六章 致谢 ···········································································33 第七章 参考文献 ·····································································34 |

|

部分图纸 截图 |

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1 南京德龙屠宰设备

南京德龙屠宰设备

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1

南京德龙屠宰设备

南京德龙屠宰设备