| 小林设计素材网

客服QQ:178308054 Email:178308054@qq.com 机械设计资料 |

相信专业,相信小林 | 小林机械资料网竭诚为您服务! |

|

|

|

| 首页

| 工艺夹具

| 数控编程

| 注塑模具

| 冲压模具

| 机械机电

| 土木工程

| 采矿通风

| 其他专业

| 购买流程

| 信誉说明

| 付款账号

| 加盟

|

|

|

|

| 您现在的位置: 主页 > 机械机电 > |

|

设计名称 |

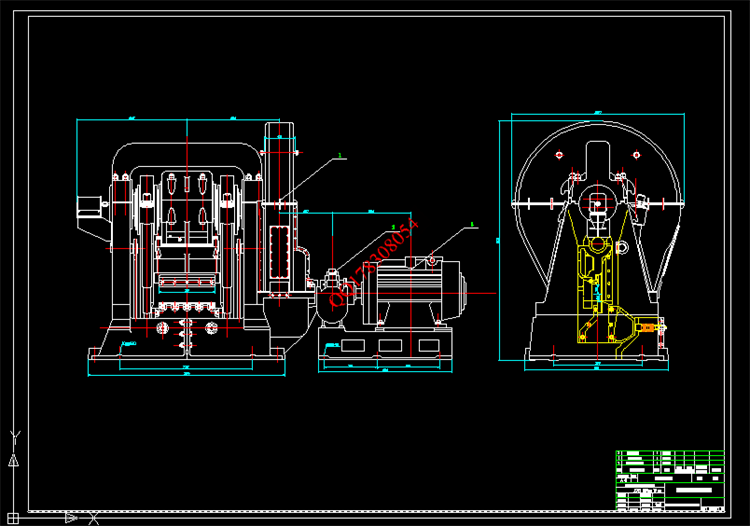

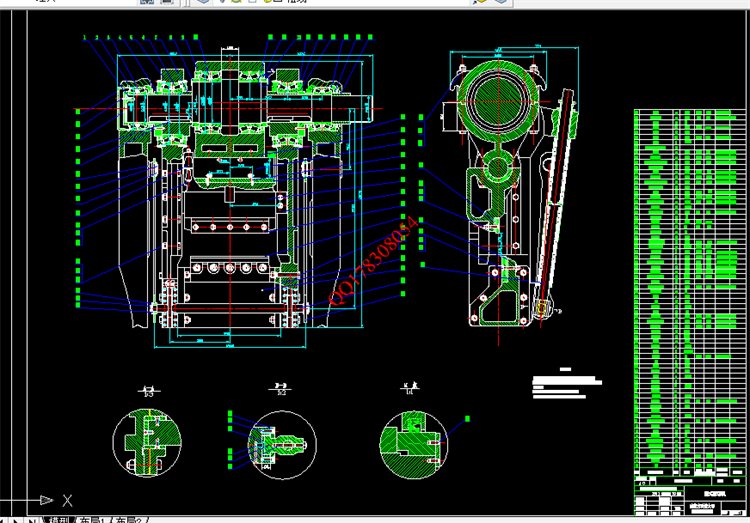

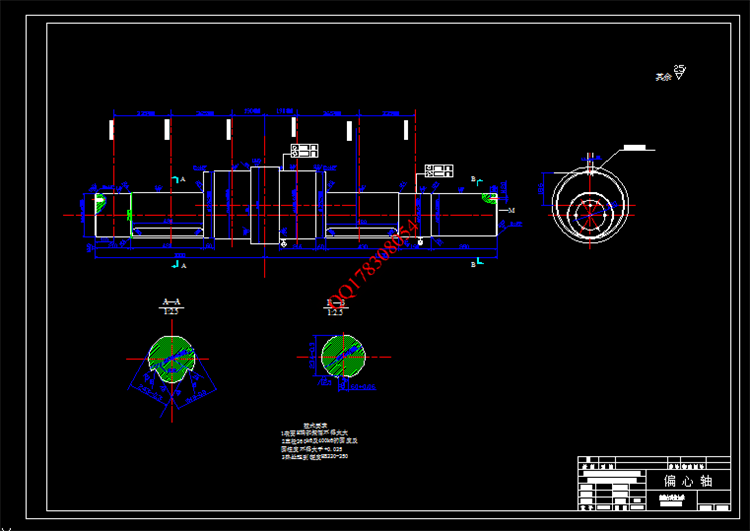

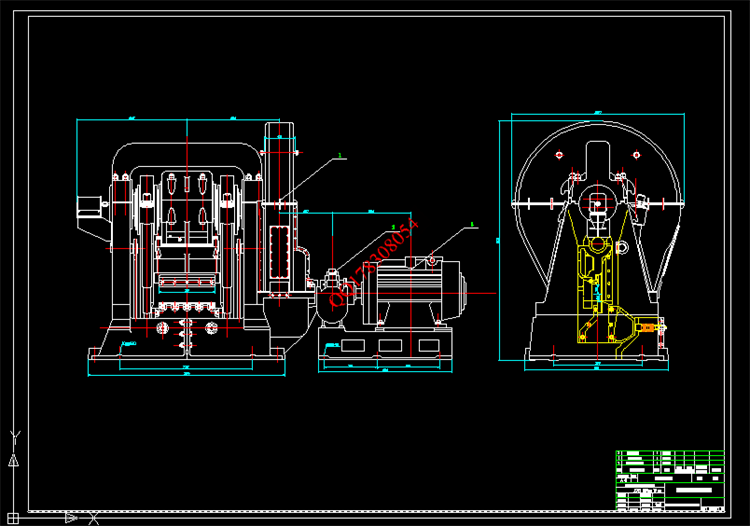

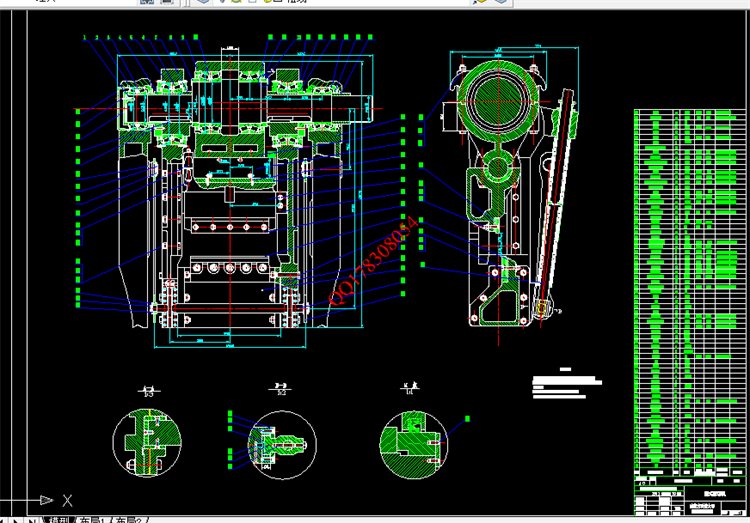

摆式剪切机设计

|

|

|

设计编号 |

B428

|

|

设计软件 |

AutoCAD,

Word |

|

包含内容 |

见右侧图片

|

|

说明字数 |

20000字 |

|

图纸数量 |

见右侧图片

|

|

推荐指数 |

较高 |

|

价格: |

价格优惠中 |

|

整理日期 |

|

|

整理人 |

小林 |

|

购买流程 |

<查看如何购买本站设计> | |

|

设计简介 |

目 录

摘要:····································································································· I

Abstract:····························································································· II

目 录································································································ III

第一章 绪论····························································································· 1

1.1课题选择的背景和目的············································································ 1

1.2热轧型钢轧机的国内外发展趋势································································· 1

1.3飞剪机的种类和用途··············································································· 2

1.3.1滚筒式飞剪机················································································· 3

1.3.2曲柄偏心式飞剪·············································································· 3

1.3.1摆式剪切机···················································································· 4

1.4摆动剪研究的内容和方法········································································· 5

1.4.1摆动剪在型钢连续机组布置和作用························································ 5

1.4.3摆动剪的结构特点和研究的内容与方法·················································· 6

1.5本课题设计参数····················································································· 6

第二章 摆式剪设计方案的选择和评述······························································ 7

2.1剪切工艺对飞剪机的基本要求··································································· 7

2.2总体设计方案······················································································· 7

2.2.1总体设计步骤················································································· 7

2.2.2摆动剪方案评述·············································································· 8

第三章 剪切力的计算················································································ 10

3.1剪切速度和剪切力················································································ 10

3.1.1摆动剪设计参数············································································· 10

3.1.2剪切机构主要参数的确定·································································· 10

3.1.3剪切速度的确定············································································· 11

3.1.4剪切力的计算················································································ 13

3.2剪切力矩的计算··················································································· 16

3.3电机型号的选择及校核·········································································· 17

3.3.1预选电机····················································································· 17

3.3.2 电机的校核·················································································· 18

第四章 主要零件的强度计算········································································ 20

4.1齿轮的强度计算··················································································· 20

4.1.1按齿面接触强度设计······································································· 20

4.1.2计算··························································································· 21

4.1.3按齿根弯曲强度设计······································································· 22

4.1.4几何尺寸计算················································································ 23

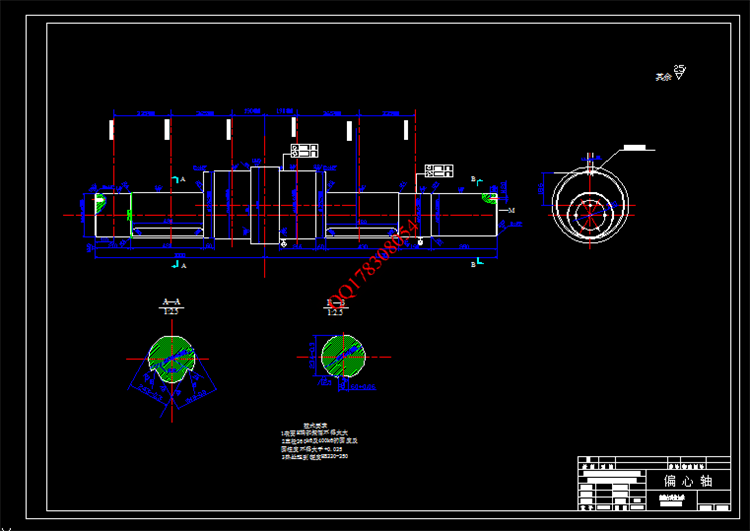

4.2曲轴的强度计算··················································································· 23

4.2.1曲轴的尺寸和材料性能····································································· 23

4.2.2曲轴的强度校核············································································· 24

4.3 轴承的计算及校核··············································································· 25

4.3.1 轴承的选择·················································································· 25

4.3.2 轴承的校核·················································································· 25

4.4 选择制动离合器·················································································· 26

4.5 刀架的设计计算·················································································· 27

4.6 切向键的计算····················································································· 28

4.4相关部件的三维实体图··········································································· 29

第五章 设备的安装与装配检验····································································· 32

5.1摆式飞剪设备主要安装部分及工作特点······················································· 32

5.1.1设备主要安装部分·········································································· 32

5.1.2工作特点····················································································· 32

5.2摆式剪安装工艺流程及关键点·································································· 33

5.2.2安装关键点··················································································· 33

5.3摆式剪安装工艺及质量控制····································································· 34

5.3.1基础检查验收················································································ 34

5.3.2中心标板、标高基准点的设置···························································· 34

5.3.3基础座浆及整体安装的施工······························································· 34

第六章 设备维修、状态监测和润滑······························································· 38

6.1设备的维修························································································ 38

6.2设备的状态监测··················································································· 39

6.3设备的润滑························································································ 40

6.3.1润滑方法的选择············································································· 40

6.3.2冶金设备润滑油清洁度管理······························································· 41

6.3.3冶金设备润滑技术的发展趋势···························································· 42

第七章 机械的可靠性设计·········································································· 44

7.1 可靠性概述······················································································· 44

7.2机械设备的有效度················································································ 45

致谢····································································································· 47

参考文献······························································································· 48

| |

|

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看.

机械毕业设计|论文 | |

|

|

|

[要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

| |

|

|

|

|

|

|

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered

by 小林机械资料商城 © 2013-2020 All Rights Reserved.

客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1  南京德龙屠宰设备 南京德龙屠宰设备 |

|

|

南京德龙屠宰设备

南京德龙屠宰设备