|

设计简介 |

设计描述:

Word版说明书一份,66页,23000字左右.

外文翻译一份

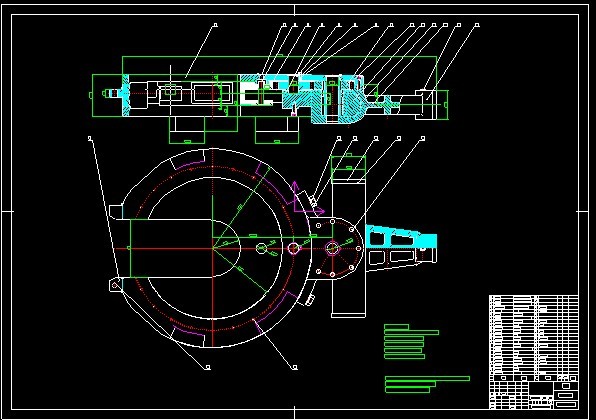

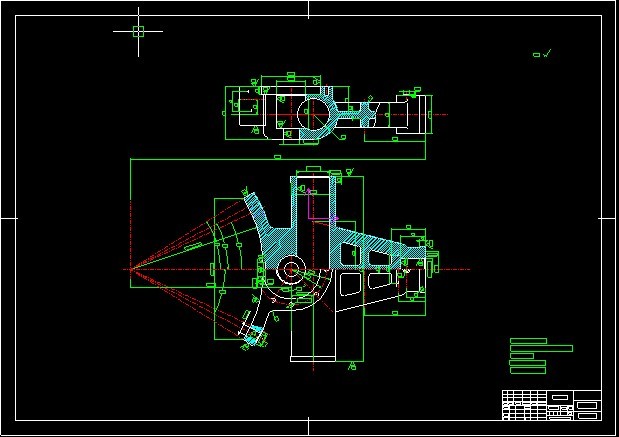

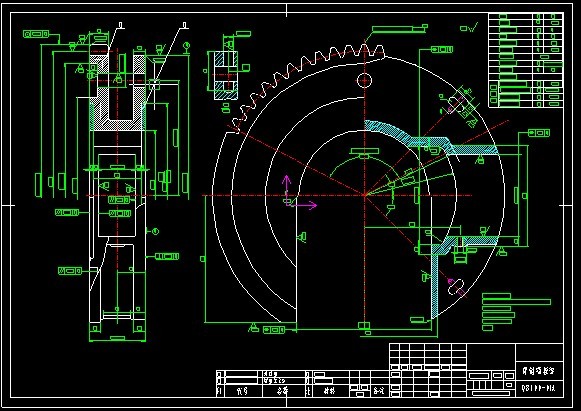

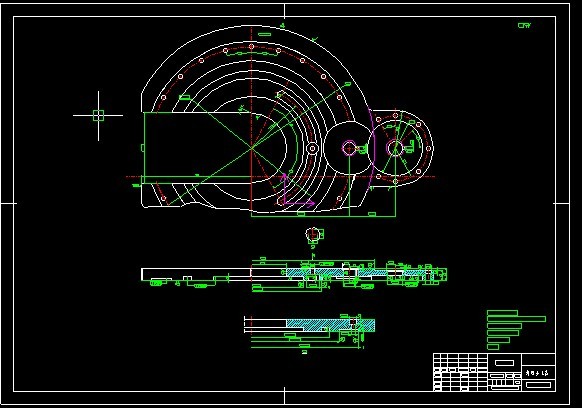

CAD版本图纸,共6:

摘要

在人类的机械创新的不断进步,使机械代替了人。以前在油田修井时或者下油管时,管与管连接时是用管钳来上扣和卸扣,现在使用这种液压钳,就给人类带来很多方便,使工作效率和安全系数提高,也减少了很多井口的工作人员,因此这是油田经常使用的卸管工具。针对修井作业中人力上卸抽油杆螺纹效率低,劳动强度大,又不能保证不同规格抽油杆所要求的上扣扭矩等问题,研制了ZQ-100型液压抽油杆钳,这种抽油杆钳由主钳,手动换向阀,液压马达,底钳,弹簧吊筒和调节弹簧等组成,在设计中省掉了转速换挡机构,同时通过改变制动板上压簧螺栓的结构,解决了制动板减薄时颚板滚子爬坡力量不足这一技术难题,介绍了这种抽油杆钳的工作原理。目前,国外钻杆动力钳的种类很多,而且产品性能及质量都相对稳定,特别是他们产品的体积与输出扭矩不会成比例变化,即使动力钳输出扭矩相当大时,其产品的体积也不会增加多少,因而适用于现场需要。而国内产品还处在研发和改进阶段,产品性能及质量都有待进一步提高,国内产品的体积和重量都随输出扭矩的增大而增大,从而导致无法适用于某些大型钻管。近10年来,中国国内生产动力钳有所增长,但相比国外我国动力钳结构复杂不方便使用与维护,使用期短等缺点,所以我国正大力发展动力钳设计改造,达到世界水平。

关键词:石油;机械创新;性能;转杆动力钳;研发改进;设计

Abstract

In recent years, with continued rapid growth of our national economy, petroleum volume of consumption of our country increase year by year. The rank has already exceeded Japan, has become the second largest petroleum following U.S.A. and consumed the country. On being pole required to pump oil, pump the oil pole pincers after developing the hydraulic pressure of Model ZQ-100, this kind pumps the oil pole pincers by the main pincers , the manual reversing valve, hydraulic motor, bottom pincers , the spring hangs tube and regulates spring ,etc. to make up , save rotational speed shift gears organization , at the same time through change , apply the brake board pigeonhole reed structure of bolt in design, solve , apply the brake board jaw board roll sub climbing strength insufficient technological difficult problem this reduce thin ,, recommend this kind pump oil pole operation principle of pincers! Main technical parameter and experimental situation in the room, employ the result to indicate live, adopt Model ZQ-100 hydraulic pressure pump oil pole pincers can reduce , release oil pole take off number of times of spiking greatly, improve and build the quality of the well and build the pace of the well. Let out difficult to avoid and fluid have a sure one but compression, so, transmission than unable and invariable, suitable for transmission than requiring strict occasion. Energy caused to leak lose, hydraulic transmission main energy is lost, in addition resistance and machinery that fluid receive among pipeline rub etc., cause sure energy to lose, cause the efficiency of hydraulic transmission to be relatively low. The viscosity of the fluid changes with temperature, as the warm change of oil, will influence the working performance of the actuator directly. In addition, have greater difficulties to adopt hydraulic transmission under the low-temperature condition or high-temperature condition. Fluid through air, will produce noise is apt to cause vibration, the ones that influenced transmission are steady. It is relatively difficult to maintain, the work load is large. At the trouble of producing, trouble reason difficult to look for, get rid of getting difficult through design, optimize, reduce, shoulder, influence as hydraulic system. At present, the kind of the motive force pincers of foreign drilling rod is numerous, and properties of product and quality are all relatively stable, especially they the products one volume and output torsion can changes proportional, even if power, when pincers quite heavy to export torsion, volume of product its how much does it increase either, suitable for needing at the scene. The domestic products are still at the stage of researching and developing and improving, properties of product and quality all remain to further improve, volume and weight of the domestic products all export the increase of the torsion to increase at the same time, thus it is unable to be suitable for some to cause and bore managing large-scaly. The past 10 years, produce power pincers increase to some extent, compare foreign of our country power pincers structure complicated to use and maintain while being inconvenient in China, the shortcoming such as being short of service time, so our country is developing the motive force pincers to design and transform in a more cost-effective manner, reach the world standard. Transfer to ZQ100 type to pole power pincers carry pincers go on, design , realize, it is safe to apply the brake, it is reliable and durable. Make the hydraulic pressure control and drive the rack to clamp the steel tube effectively.

Key words: Petroleum; Machinery innovates; Performance ; Transfer to the pole motive force pincers ; Research and develop and improve; Design

目 录

1 绪 论 1

1.1 液压动力钳概述 1

1.1.1 液压动力钳的发展状况 1

1.1.2 液压动力钳的应用 2

1.2 液压动力钳的结构及工作原理 3

1.2.1 液压动力钳的结构及特点 3

1.2.2 液压动力钳的工作原理 4

1.3 液压动力钳技术参数及特点 5

1.3.1 ZQ-100型液压动力钳的技术参数 5

1.3.2 液压动力钳的技术特点 5

1.4 液压动力钳的的操作说明 6

1.4.1 液压动力钳的的安装 6

1.4.2 液压动力钳的操作 7

1.4.3 液压动力钳的维护与润滑 7

1.4.4 液压动力钳的常见故障及排除方法 8

2 ZQ-100型钻杆动力钳的背钳总体设计 9

2.1 ZQ-100型钻杆动力钳的背钳概述 9

2.2 ZQ-100型钻杆动力钳的背钳结构设计 9

2.3 背钳结构设计中的问题 10

3 ZQ-100型钻杆动力钳的背钳液压缸设计 12

3.1 液压缸的类型和结构形式选择 12

3.2 液压缸基本参数确定 12

3.2.1 液压缸工作负载及工作压力 13

3.2.2 缸筒内径及柱塞杆直径 13

3.2.3 液压缸最大工作行程和最小导向长度 16

3.3 液压缸的强度及刚度校核 17

3.3.1 缸筒壁厚的校核及外径计算 17

3.3.2 液压缸柱塞杆强度验算 18

3.4 液压缸稳定性验算 18

3.5 液压缸的安装试验与维护 19

4 ZQ-100型杆动力钳的背钳传动设计 21

4.1 背钳传动概述 21

4.2 背钳传动设计 21

4.3 轴的设计 23

4.3.1 轴的结构设计 23

4.3.2 轴的强度计算 23

4.3.3 轴的刚度计算 23

4.3.4 轴的稳定性 27

4.4 齿轮系的设计 27

4.4.1 齿轮系的传动比 28

4.4.2 齿轮的强度计算 28

5 结论 45

6 技术经济分析 44

致 谢 47

参考文献 48

附录A译文 50

附录B英文文献 56

|