|

设计简介 |

设计描述:

文档包括:

word说明书一份,共53页,约22000字

CAD版本图纸,共24张

PROE三维,一套

目录

Abstract 6

第1章 绪论 9

1.1前言 9

1.2国内外蔬菜钵苗取苗机构的发展概述 11

1.2.1我国蔬菜钵苗移栽机械化发展概况 11

1.2.2我国蔬菜钵苗移栽机存在的问题 12

1.2.3我国蔬菜钵苗移栽机存在问题解决途径分析 12

1.2.4国外蔬菜钵苗自动移栽机的发展和研究成果 13

1.2.5蔬菜钵苗移栽机发展方向 14

1.3国内取苗机构存在的主要问题和发展方向 15

1.3.1国内取苗机构发展存在的主要问题 15

1.3.2国内蔬菜取苗机构的发展方向 15

1.4本文的研究目标 16

1.5本文的主要工作及内容安排 17

1.6本章小结 17

第2章 蔬菜钵苗取苗机构的运动学分析 18

2.1取苗爪工作要求的实现 18

2.2蔬菜钵苗取苗机械手的机构组成与工作原理 19

2.3 椭圆齿轮传动的运动分析 21

2.3.1 椭圆齿轮的啮合特性及优点 21

2.3.2 椭圆齿轮的角位移、角速度和传动比分析 22

2.4蔬菜钵苗取苗机械手运动学模型的建立 24

2.4.1运动学分析符合的说明 24

2.4.2蔬菜钵苗取苗机械手位移分析 25

2.4.3机械手上各点位移方程和各构件角位移方程 26

2.4.4 机构上各点的速度方程和各构件角速度方程 28

2.4.5 机械手上各点的加度方程和各构件角加速度方程 29

2.5本章小结 31

第3章 蔬菜钵体苗自动移栽机取苗机构的参数优化 32

3.1优化目标与变量 32

3.2辅助分析优化软件 32

3.2.1人机交互简介 33

3.2.2本课题人机交互软件介绍 34

3.2.3椭圆齿轮参数计算 35

3.2.4取苗机构参数优化步骤 35

3.2.5取苗爪尖点的速度分析 36

3.3本章小结 38

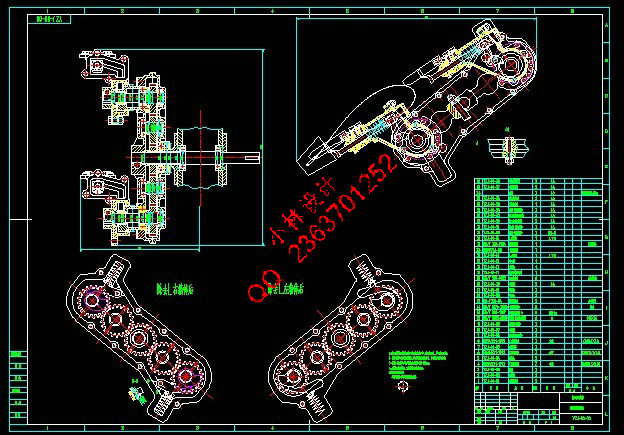

第4章 蔬菜钵苗自动移栽机取苗机构的结构设计 38

4.1蔬菜钵体自动移栽机取苗机构的整体结构设计 38

4.2取苗臂机构设计 40

4.3 CAD软件介绍 41

4.3.1 CAD二维取苗机构零件图 41

4.4 Proe软件介绍 43

4.4.1 三维Proe取苗机构零件图 44

4.5总装配图 45

4.6 本章小结 46

第5章 总结与展望 47

5.1 总结 47

5.2 进一步的展望 48

致 谢 49

参考文献 50

附录 52

摘 要

移栽是蔬菜生产过程中的重要环节之一,移栽具有对气候的补偿作用和使作物生育提早的综合效益,可以充分利用光热资源,其经济效益和社会效益均非常可观。目前,国内正在应用的移栽机械多为半自动移植机,半自动移栽机靠手工送苗,效率低,劳动强度大,而国内自动移栽机的研究刚刚起步,自动移栽机从取苗到植苗都由机械自动完成,效率高。国外虽有一些自动移栽机应用于生产,但还处于不断研究与推广阶段。而取苗机构是制约自动移栽机发展的“瓶颈”,也是制约蔬菜大规模种植的关键问题之一。因此设计一种新型的取苗机构替代手工取苗,已成为我国蔬菜种植业发展的迫切需要。

本文总结吸收了国内外各种取苗机构的优缺点,在实验室已有研究成果的基础上,设计了一种新型蔬菜钵苗取苗机构,该机构可以单独作为取苗机构,实现自动取苗;或通过改进部分结构参数,可以集栽取功能于一体,即取苗和栽植苗动作都由该套机构完成。该蔬菜钵苗取苗机构结构简单,工作可靠,取苗效率高。本文主要的研究内容如下:

1.根据蔬菜钵苗取苗的技术特点和农艺要求,模拟人工取苗的轨迹、动作和姿态要求,发明蔬菜钵苗取苗机构,满足机械取苗特殊的工作轨迹要求,比现有的蔬菜取苗机构工作效率高,并且工作平稳。

2.论述了该取苗机构的工作原理和结构特点,建立取苗机构的运动学模型。

3.以建立的运动学模型为基础,基于可视化开发平台VB6.0,通过其软件分析蔬菜钵苗取苗机构辅助分析与优化软件(软件登记号:2011SR030044),介绍了该软件的人机交互界面及功能,基于该软件,解决了该机构运动学多目标优化的难点。

4.根据蔬菜取苗农艺要求,提出蔬菜钵苗取苗机构参数优化的目标和优化方法,分析各参数变化对取苗机构运动特性的影响,利用自主开发软件,采用人机交互的优化方法,优化出取苗机构的结构参数,满足蔬菜钵苗取苗的工作要求。

5.按照优化得到的结构参数,进行蔬菜钵苗取苗机构的总体设计,讨论了设计中应该注意的问题,最后在ProE、CAD下完成装配图和各零件的设计。

6.建立取苗机构的三维实体模型,对其进行虚拟装配。

关键词:蔬菜钵苗;取苗机构;工作机理;参数优化;试验研究

Optimal and Design of Vegetable Plug Seedling Pick-up Mechanism of Planetary Gear Train with Ellipse Gears and Incomplete Non-circular Gear

Abstract

Transplanting is an important process of vegetable procreating, which has the function of compensating varying climate and shifting the procreating of plants to an earlier time. It helps the plants to use the source of light and temperature sufficiently, which will make considerable economical and social benefits. At present, most transplanting machines are semi-automatic transplanting machines ,they need pick up plug seedling by man ,which have high work intensity and low work efficiency ,and domestic research on automatic transplanting machine is just beginning . Automatic transplanting machine can pick up plug seedling and transplanting plug seedling by themselves ,which have low work intensity and high work efficiency. The overseas have automatic transplanting machine be applied in production,but the application and research on automatic transplanting machine is developing.Thus the pick up plug seedling machine is the key issues,which restricted the development of automatic transplanting machine and at same time ,which is also restricted the development of the plants of vegetable . So it's a pressing requirement to design a new kind of pick up plug seedling machine.

This paper concludes the merits and demerits of several kinds of transplanting machines from both domestic and abroad. Based on the achieved research result, a new vegetable plug seedling pick-up mechanism of planetary gear train with ellipse gears and incomplete non-circular gear has been designed. This vegetable plug seedling pick-up can be used as seedling fetching mechanism lonely to realize fetching seedlings automatically. Besides, if the mechanism parameters of this mechanism have been optimized properly, the motion of fetching seedlings and transplanting seedlings can both be realized by this mechanism. This vegetable plug seedling pick-up mechanism has simple structure and reliable performance. The main content of this paper is listed as bellow:

1. According to the technological characteristics and agricultural requirements, imitate the requirements of trajectory, motion and attitude of manual pick up plug seedling, invent the vegetable plug seedling pick-up mechanism, which can satisfy the special working trajectory requirements of fetching and pick up plug seedlings automatically. This new vegetable plug seedling pick-up mechanism has higher working efficiency, steadier transmission and less vibration than existing mechanism.

2. The working principle and structural features of this automatic vegetable plug seedling pick-up mechanism has been discussed and the kinematic mathematical model of this mechanism has been established.

3.Based on the established kinematic mathematical model and Visual Basic 6.0, develop the kinematic aided analytical and optimal software of this vegetable plug seedling pick-up mechanism (Register Number: 2011SR030044). Introduce the human-computer interactive interface and functions of this software. By this software, the difficulty of optimization with multiple kinematic objects of this mechanism can be solved.

4. According to the agricultural requirements in our country, put forward the parametric optimal objects and methods of the vegetable plug seedling pick-up mechanism. Analyze the influence of parameter vitiation on kinematic characteristics of this vegetable plug seedling pick-up mechanism. Take advantage of the developed software, use the optimization method of human-computer interactive, and obtain the structural parameters which can satisfy the working requirements of automatic vegetable pot seedling transplanting.

5. In accordance with the obtained structural parameters, design the ensemble of the vegetable plug seedling pick-up mechanism; discuss the problems which should be noticed in the process of designing. Finally finish the design of parts and the assembly drawing basing on ProE and CAD.

6. Establish the solid model of all parts of this vegetable plug seedling pick-up mechanism in UG6.0 and then carry out the virtual assemble.

Keywords: Vegetable plug seedling; Pick-up mechanism; Work principle; Parameters optimization; Test study

|