|

设计描述:

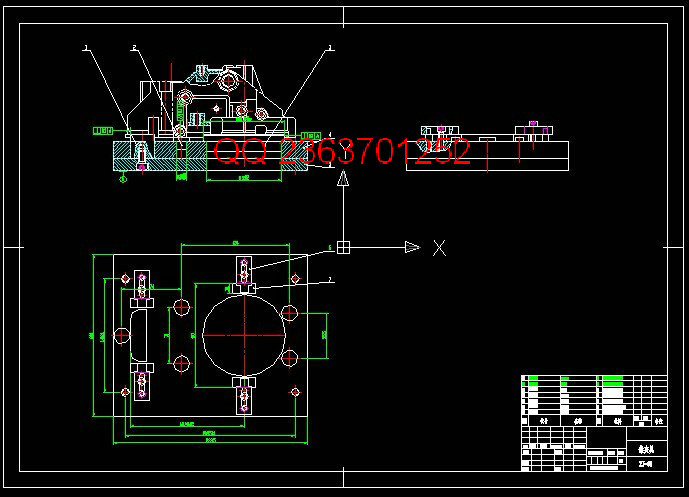

文档包括:

Word版设计说明书1份,共39页,约17700字

外文翻译一份

任务书一份

CAD版本图纸,共9张

目 录

第一章 引言 1

1.1论文背景及研究意义 1

1.2组合机床发展概况 1

1.2.1组合机床的由来 1

1.2.2组合机床技术装备现状与发展趋势 1

1.3本文研究的主要内容 2

第二章 组合钻床总体设计 4

2.1组合钻床工艺方案的制定 4

2.2 7孔组合钻床配置型式及结构方案的确定 4

2.3主要参数的计算 5

2.3.1确定切削用量,计算各主轴转速 5

2.3.2确定切削力F、切削转矩M、切削功率P 6

2.4组合机床总体设计 6

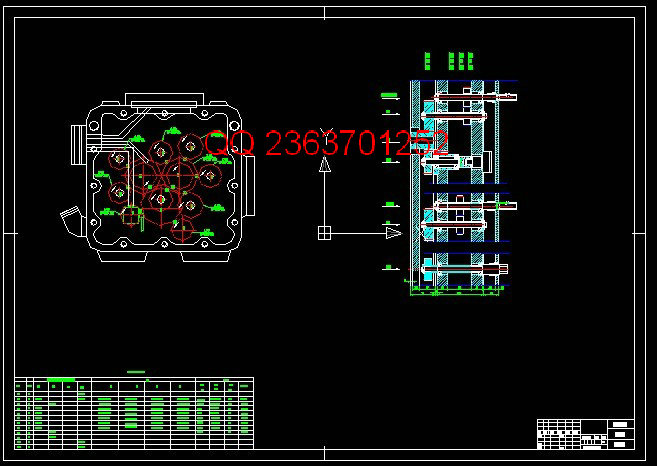

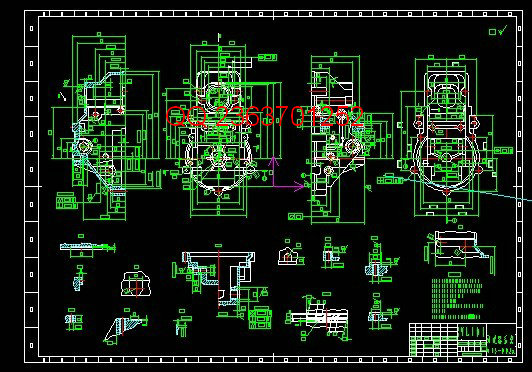

2.4.1被加工零件工序图 7

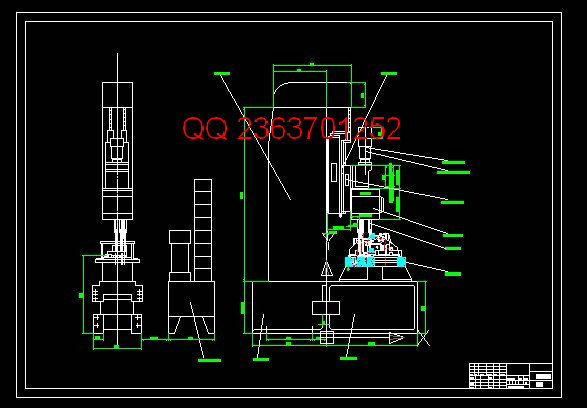

2.4.2加工示意图的设计 71

2.4.3机床联系尺寸图的绘制 11

2.4.4生产率计算卡 14

第三章 主轴箱设计 16

3.1绘制主轴箱设计原始依据图 16

3.2 主轴结构形式的选择及动力计算 17

3.3传动系统的设计和计算 18

3.4多轴箱的坐标计算 21

3.5主轴箱通用轴类零件选择 24

3.6 主轴及通用传动轴结构形式的选择方案 26

3.7 通用齿轮及其他通用件及传动轴轴承型号的选用 26

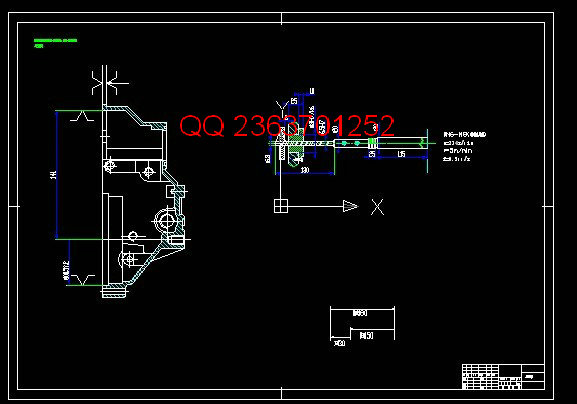

第四章 夹具设计 27

4.1 机床夹具的概述 27

4.2定位支承系统设计 27

4.2.1定位支承系统的设计原则 27

4.2.2定位支承元件及其布置 28

4.3导向装置设计 28

4.3.1导向装置的作用 28

4.3.2固定式导套的设计 28

4.3.3固定钻模板结构设计 29

4.4夹紧机构设计 30

4.4.1夹紧方案的确定 30

结论 32

致谢 33

参考文献 34

调速器后壳7孔组合钻床铰孔设计

专业班级:机械0902 学生姓名:李铭扬

指导老师:葛涛 职称:讲师

摘要 本文从企业实际需求出发。在全面分析被加工零件的结构特点、尺寸精度、被加工孔相互之间位置精度、表面粗糙度和技术要求的基础上,指出采用现有设备不仅工人劳动强度大,生产率低,而且零件加工精度难以保证。根据实际需要,研制出了7孔单工位组合钻床。

本文首先通过分析比较,确定了7孔单工位组合钻床的配置型式及结构的最佳方案,遵循机械设计中标准化、通用化、系列化原则, 给出机床的总体设计,绘制出代表机床总体设计的被加工零件工序图、加工示意图、机床联系尺寸图和生产率计算卡。对本机床的关键部分:主轴箱和夹具的结构进行了创新设计。由于在本台组合钻床上髓同时加工7个孔,孔多、间距小,采用常规方法排箱无法实现4孔的工序集中的加工方案。本钻床的主轴箱传动系统通过采用变位齿轮和滚针轴承等结构方面的创新设计,将常规方法下不能完成的排箱成为可能。本台组合钻床夹紧机构,采用了快速螺旋夹紧机构。减少了装卸零件所用时间,提高了生产效率。

按上述设计方案制造出的4孔单工位组合钻床与原方案加工工件的实验结相比较,有以下几个突出的优点:

1.提高了生产率

在本台组合钻床上加工该零件,由于是8把刀具同时加工,缩短了辅助时间,加工循环时间仅为2.7min,而在原普通钻床上加工此工件,加工循环时间平均需要15分钟,生产率提高了4.6倍。

2. 提高了加工精度

在普通钻床上加工,由于是采用多工步,各孔的位置精度不易保证,废品率一般在2%:采用7孔组合钻床,因为在设计的每一个环节,都严格控制设计零件的精度,且是多刀同时加工,所加工出的零件位置精度均在要求范围内,废品率为0。通过实际运行结果证明:该4孔单工位组合钻床确实达到了“体积小,重量轻,结构简单,使用方便,效率高,质量好”的要求。既大大减轻了工人的劳动强

度,又给厂家带来了可观的经济效益。

关键词: 组合钻床 主轴箱 夹具设计 传动设计

The meaning of the designation of a combination drilling machine for R801flyweght

ABSTRACT: In view of the actual conditions of enterprises and on the basis of overall analyzing work piece structure features,accuracy of size,surface roughness,accuracy of distance between drilled holes and other technical requirements,this article points out that the existing equipments used to manufacture work pieces may result in lower productivity,greater intensity of labor and worse working accuracy.Therefore,it is necessary to develop a new type of 4 hole single working position combination drilling machine.

Through analysis and comparison,the article has determined the best project of the structure and the disposition of the 4 holes combination drilling machine.According to the principle of standardization,generalization and serialization in machine design,the article offers the master design of the drilling machine,the process drawing of work piece,the working diagram,the connection dimensional drawing of the drilling machine and the calculating card of productivity.In some key parts of the drilling machine,there are certain new designs on the structure of the spindle box and the fixture.With 4 hole drilled simultaneously on the drilling machine,in addition to dispersive arrangement of hole position,the 4 holes drilling program cannot be completed in conventional way.In the transmission system of 4 hole drilling machine are used some new structural designs such as pin bearings and position-changeable gears,so that the arrangement of hole position,which cannot be finished in conventional way,can be accomplished.The combination drilling machine is applied a fast spiral pinch machinery whose features are not only shortens the time consumed in loading and unloading work piece but also enhances productivity.

After the experimental result of the new type of 4 hole combination drilling machine is compared with the one of the original working program,there are following advantages:

1.Enhancing productivity

If the work piece is cut with 4 drills on the combination drilling machine,the auxiliary time would be shortened and the working cycle time would be limited within 2.7min.On the other hand,if the work piece is cut on the general-purpose drilling machine,its working cycle time would take 15min on an average,the productivity would increase by 4.6 times.

2.Improving working accuracy

The reject rate of work piece cut on the general-purpose drilling machine usually reaches to 2﹪ because of its multi step working procedure,so it is difficult to secure the spacing accuracy of every hole.Yet the 4 hole combination drilling machine may reach to 0.This is because the working accuracy of work piece is strictly controlled at each design point and the spacing accuracy of work piece cut by multi tool is limited within the desired scope.The result checked through actual operation proves that the 4 hole combination drilling machine really meets the requirement of “small in volume,light in weight,simple in structure,convenient in use,high in efficiency and excellent in quality.”This type of drilling machine reduces the labor strength largely and brings enterprises huge economic benefits,either.

Key Words:Combination drilling machine Design of transmission system

Spindle box Design of fixture

|