|

设计简介 |

设计描述:

文档包括:

word版设计说明书一份,30页,约16000字

CAD版本图纸,共3张

摘要

随着科学技术的迅猛发展,数控机床已经成为衡量一个国家机械制造工业水平的重要标志。采用经济型数控系统对普通机床进行数控化改造,尤其适合我国普通机床拥有量大,生产规模小的具体国情。机电一体化技术涉及机械、电子、以及控制等多门学科,是现代工业最主要的基础技术和核心技术之一,是衡量一个国家机械装备发展水平的重要标志。虽然这门学科还正处于发展阶段,许多理论还处于研究和完善阶段,但是它代表着机械工业技术革命的前沿方向,是综合国力的又一具体体现。因此,我们应该重视该学科的研究,并大力发展这门学科,逐渐缩小与日美等发达国家的差距。本次设计是对CA6140普通车床的数控化改造。在国内,盛行普通车床改造成数控车床,此设计就是针对着这以目的而设计的,这就降低了生产成本,缩短了工业化的进程,同时为广大的生产厂家所接受。

此设计主要是结合国内的具体国情,针对于广大的用户所设计的。远远比不上那些外国的设备所达到的精度。当然,时代在发展,随着我国的正和国力迅速攀升,在不久的将来那些精度要求比较高的数控设备一定出现在中国的大部分企业中。

关键字:数控改造 机电一体化 国情 学科研究

Abstract

Along with the science technical fast fierce development, number's controling tool machine has already become the important marking which measures a national machine manufacture industry level.Adopt the economic number controls system to carry on a number to control to turn a reformation to the common tool machine, particularly in keeping with our country the common tool machine own to have great capacity, the small concrete state of the nation of the production scale.The machine electricity integral whole turns a technique to involve a machine, electronics, and control etc. several academicses, is one of the foundation technique and core techniques of modern and industrial most, is the important marking which measures a national development level of the machine material.Although this academics is still be placed in a development a stage, many orieses are still placed in research and perfect stage, it represents the machine industrial technique revolution of ex- follow a direction, is comprehensive another concrete body of national strength now.Therefore, we should value the research of that academics, and strongly develop this academics, contract to wait with day the United States gradually flourishing nation of margin.This design is to control to turn a reformation to the number of CA6140 common lather.At the domestic, the widely accepted common lather reforms into a number to control lather, this design is to aim at this with the purpose but design of, this lowered production cost and shortenned industrialization of the progress is a large production factory in the meantime, house accept.

This design is mainly to combine local concrete state of the nation and aim at at what large customer design.Far and far can not compare with the accuracy that the equipments of those foreign countries attain.Certainly, the ages is in the development, along with our country of positive with the national strength quickly increase, in the near future those greatly parts of business enterprises that the accuracy requests higher number to control an equipments and must appear in China in.

Key word:The number controls a reformation The machine electricity integral whole turn State of the nation The academics study

目录

绪论………………………………………………………………1

1. 数控机床的基本知识…………………………… 2

1.1数控机床的发展趋势…………………………………………………2

1.2数控机床的组成………………………………………………………4

1.3机床的运动性能指标…………………………………………………5

1.4数控机床机械结构的组成、特点……………………………………5

1.5数控机床主传动系统的特点及其要求………………………………7

2 总体方案设计…………………………………………… 10

2.1设计任务 10

2.2.总体方案确定 10

2.2.1系统的运动方式与伺服系统的选择 10

2.2.2计算机系统 10

2.2.3机械传动方式 11

3 电机的选择和脉冲当量的选择…………………………… 11

3.1确定系统脉冲当量 11

3.2电机的选择 12

3.2.1纵向进给步进电机的计算 12

3.2.2横向进给步进电机的计算 12

4. 导轨的设计………………………………………………… 13

4.1滚动导轨的优点 13

4.2选择滚动导轨的结构形式 13

4.3滚动导轨预紧方式的确定 13

4.4滚动导轨几何参数的确定 14

4.4.1滚动体尺寸和数目的选择 14

4.4.2滚动导轨的长度 14

4.5塑料导轨的应用 15

4.6贴塑导轨 15

5. 纵、横向自动走刀机床进给伺服系统机械部分的设计 15

5.1设计任务 15

5.2总体设计的方案确定 15

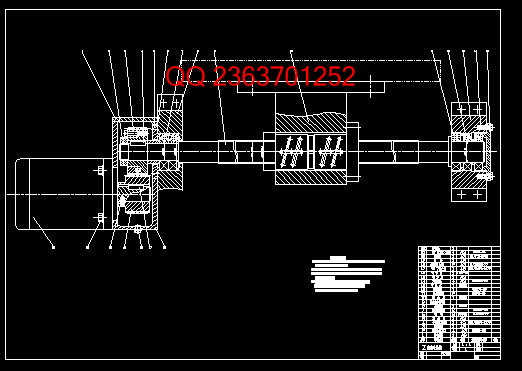

5.3 纵向自动走刀机床进给伺服系统机械部分的设计 16

5.3.1切削力计算 17

5.3.2 滚珠丝杠设计计算 17

5.3.3齿轮及转矩的有关计算: 19

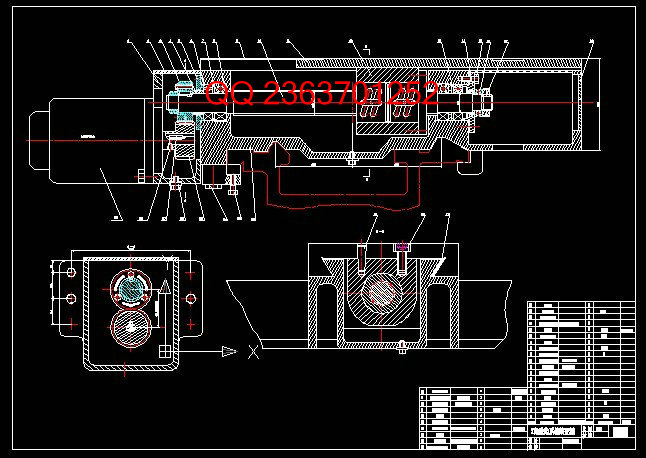

5.4 横向自动走刀机床进给伺服系统机械部分的设计 21

5.4.1切削力计算 21

5.4.2 滚珠丝杠设计计算 21

5.4.3齿轮及转矩的有关计算: 24

6 微机数控系统硬件电路的设计…………………………… 25

6.1控制系统的功能 25

6.2采用软件环形分配器 26

6.3.自动回转刀架的控制 26

6.4.螺纹加工的控制 26

6.5地址编码 26

7. 安装………………………………………………………… 27

7.1 纵向进给系统安装 27

7.2 横向进给系统安装 27

7.3 刀架安装 27

7.4 数控系统箱安装 27

7.5 编码器安装 27

8. 结论………………………………………………………… 28

9. 致谢……………………………………………………… 29

10. 参考文献……………………………………………………… 30

附图一 CA6140纵向伺服进给单元装配图

附图二 CA6140横向伺服进给单元装配图

附图三 CA6140机床电气控制原理图

|